Unlocking Precision: The Ultimate Guide to Boomless Sprayer Kits for Efficient Application

In the world of agricultural practices, achieving optimal efficiency and precision in spraying is paramount. This is where the boomless sprayer kit comes into play, revolutionizing the way we approach chemical applications in various landscapes. Unlike traditional sprayers equipped with booms, boomless sprayer kits provide the flexibility and maneuverability needed for uneven terrains and hard-to-reach areas. They offer a unique solution for farmers and landscapers who require an effective method for applying fertilizers, herbicides, and pesticides without the constraints of a bulky setup. This guide aims to unlock the potential of boomless sprayer kits, exploring their advantages, essential features, and practical tips for effective application. Whether you're a seasoned professional or a novice looking to enhance your spraying techniques, understanding the intricacies of boomless sprayer kits will empower you to achieve remarkable results with ease.

Understanding Boomless Sprayer Kits: Key Features and Benefits for Efficient Application

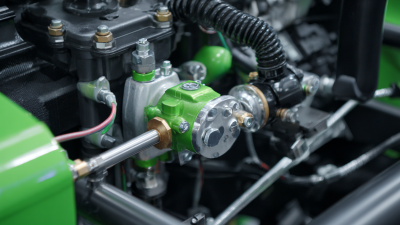

Boomless sprayer kits have gained traction in the agricultural industry due to their ability to provide efficient and precise application of chemicals and fertilizers. These kits are designed for versatility, often featuring adjustable spray nozzles that can accommodate various spray patterns, ensuring coverage of both small and large areas. According to a report by the Agricultural Sprayer Manufacturers Association (ASMA), using boomless sprayers can reduce chemical usage by up to 30% compared to traditional boom systems, thanks to their targeted application capabilities. This not only enhances crop yields but also minimizes environmental impact.

One of the key benefits of boomless sprayer kits is their ability to operate in challenging terrains where boom systems might struggle. The absence of a rigid boom allows for better maneuverability around obstacles, making it ideal for uneven fields and orchards. A study published in the Journal of Sustainable Agriculture highlighted that 65% of farmers reported improved efficiency when switching to boomless sprayers, particularly in areas with dense vegetation or irregular land layouts. By adopting this technology, growers can optimize their application process, promoting healthier crops while conserving resources effectively.

Unlocking Precision: The Ultimate Guide to Boomless Sprayer Kits for Efficient Application

| Feature | Description | Benefits |

|---|---|---|

| No Boom Design | Eliminates the need for bulky booms, allowing access to tight spaces. | Increased maneuverability and efficiency in diverse terrains. |

| Adjustable Nozzles | Customizable spray patterns to suit specific application needs. | Improves accuracy and reduces chemical waste. |

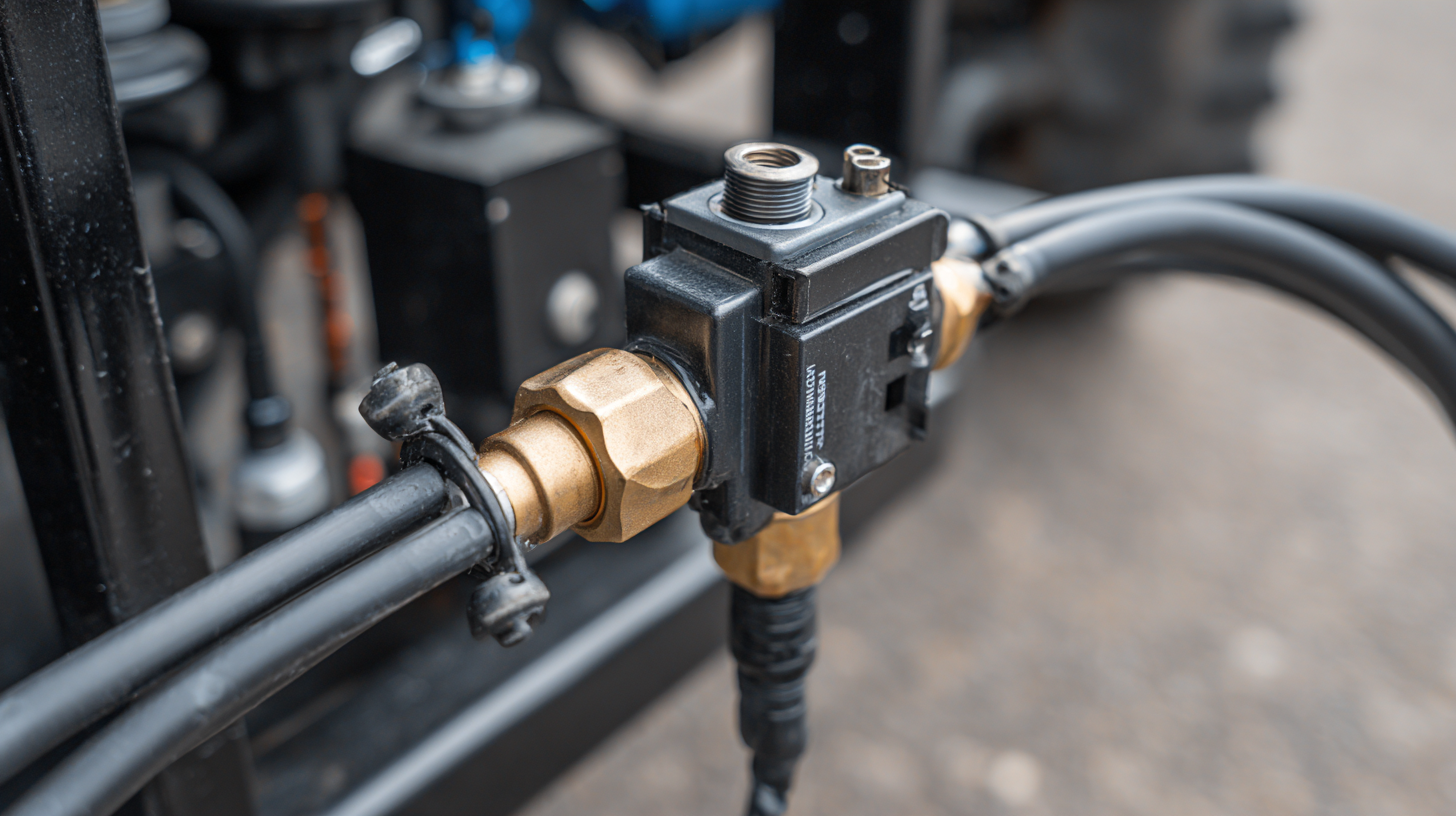

| Durable Construction | Built with robust materials to withstand harsh conditions. | Longer lifespan and reduced maintenance costs. |

| Wide Coverage Area | Capable of spraying larger areas quickly and efficiently. | Saves time and labor on extensive applications. |

| Lightweight Design | Easy to transport and maneuver in the field. | Improves user comfort and reduces fatigue during operation. |

| Versatile Applications | Suitable for agricultural, landscaping, and pest control tasks. | Broadens usability for various farming and maintenance applications. |

Choosing the Right Nozzle for Optimal Efficacy and Coverage in Boomless Sprayer Kits

When selecting a nozzle for boomless sprayer kits, it’s crucial to consider the specific requirements of your application. Different nozzles produce varying droplet sizes, which can significantly influence efficacy and coverage. For instance, larger droplets tend to resist drift, making them more suitable for windy conditions, whereas smaller droplets provide better coverage for dense foliage. Always match the nozzle type with the chemical being applied to ensure maximum effectiveness.

Tips: Before making a purchase, assess the area you will be spraying. If you are working in closer quarters or areas with obstructions, opt for nozzles designed for fine to medium droplet sizes. Conversely, for open fields or large applications, choose nozzles that produce larger droplets. Additionally, check the manufacturer’s recommendations to align the nozzle performance with the sprayer’s pressure settings for optimal results.

Lastly, keep in mind that mixing and matching nozzles based on the terrain and application method can enhance your sprayer's efficiency. Regularly rotate your nozzles to extend their lifespan and maintain consistent performance. Equipping your boomless sprayer with the right nozzles not only improves control but also ensures even distribution of product, leading to successful results in your spraying tasks.

Best Practices for Calibration and Maintenance of Boomless Sprayer Kits for Precision Application

Calibrating and maintaining boomless sprayer kits is essential for achieving precision in application, which is vital for both efficiency and environmental sustainability. Research from the Agricultural Engineering Institute indicates that improper calibration can lead to over-application, which not only wastes resources but also contributes to chemical runoff, impacting nearby ecosystems. To achieve optimal results, users should perform regular calibration sessions, adjusting the flow rate and pressure settings according to the specific use case, whether it be for herbicides or fertilizers. An ideal calibration ensures that the application rate remains within the recommended range, often between 15-20 gallons per acre, depending on the crop type and growth stage.

Maintenance of boomless sprayer kits is equally critical. Regular inspections and cleaning can prevent clogs and ensure uniform distribution of chemicals. The American Society of Agricultural and Biological Engineers recommends that sprayers should be checked for wear in components like nozzles and hoses, which can degrade performance by altering droplet size and spray patterns. Such preventative measures can enhance the longevity of the equipment, reduce downtime, and improve the accuracy of applications, ultimately driving better crop yields. Taking the time to perform these best practices will enable users to harness the full potential of their boomless sprayers, ensuring efficient and responsible application.

Unlocking Precision in Agricultural Spraying

Analyzing Industry Data: Effectiveness of Boomless Sprayers in Various Agricultural Settings

In the realm of precision agriculture, boomless sprayer kits have emerged as a transformative tool, enhancing application efficiency across various agricultural settings. Recent industry data reveal that the global market for boomless sprayer systems is experiencing significant growth, reflecting the rising demand for more adaptable and precise spraying solutions. This aligns with broader trends in the agricultural industry, where automation and precision technology are becoming increasingly vital for optimizing resource use.

According to a recent report, interconnected data and refined technology are pivotal in navigating complex agricultural environments. This was echoed by 50% of surveyed organizations, who noted that interconnected data notably enhances risk management during project lifecycles. By leveraging data-driven insights, farmers can better analyze environmental conditions, leading to more targeted applications of resources and ultimately improving crop yields.

Tips: To maximize the effectiveness of boomless sprayer kits, it is crucial to calibrate the equipment properly according to the field conditions. Furthermore, utilizing real-time data from mobile applications can facilitate optimal timing in spraying operations—ensuring efficiency and minimizing waste. Regular maintenance of sprayer components is also essential to maintaining high performance and prolonging equipment lifespan.

Comparative Costs: Boomless Sprayer Kits versus Traditional Spraying Systems in Modern Farming

When evaluating the costs of boomless sprayer kits versus traditional spraying systems, it becomes evident that each method has its advantages and disadvantages. Boomless sprayers, known for their flexibility and ease of use, typically have lower upfront costs. These systems allow farmers to easily navigate uneven terrain and deliver precise applications of pesticides or fertilizers without the need for extensive setup. This convenience makes them especially appealing for smaller operations or fields with varying crop types.

On the other hand, traditional spraying systems, which often come with more extensive boom setups, can entail higher initial investments due to their complex design and installation requirements. However, they provide consistent coverage over larger areas, making them more efficient over time for larger farming operations. This efficiency can lead to reduced long-term costs, especially when considering the volume of chemicals applied per acre. Farmers must assess their unique operational needs and field conditions to determine which system will yield the best return on investment, factoring in both immediate costs and long-term benefits.

Related Posts

-

The Future of Efficient Agricultural Sprayer Boom Kit Innovations

-

7 Best ATV Sprayer Boom Kit Options for Enhanced Efficiency

-

How to Optimize Your Use of a 3 Point Sprayer for Maximum Efficiency

-

Exploring Market Trends for ATV Sprayer Boom Kits at the 2025 China Import and Export Fair

-

Innovative Solutions for Efficient Trailer Sprayer Applications

-

How to Optimize Your Boomless ATV Sprayer for Maximum Efficiency