What is a Sprayer Nozzle and How Does It Work?

Sprayer nozzles are essential tools in various applications, from agriculture to household cleaning. They control the flow and direction of liquids, ensuring even coverage. Understanding how sprayer nozzles work can help improve efficiency and effectiveness.

Sprayer nozzles come in different shapes and sizes. Each design serves a specific purpose, impacting spray patterns and droplet sizes. For instance, a fan nozzle sprays a wide, flat pattern. In contrast, a cone nozzle creates a focused spray. Choosing the right nozzle can make a significant difference in performance.

Despite their importance, many overlook sprayer nozzles in their maintenance routine. Clogged nozzles can lead to uneven application, wasting resources. Regular checks and cleaning can enhance functionality. In many operations, users might not realize the impact of the nozzle choice. The right nozzle can save time, water, and chemicals, leading to better results.

What is a Sprayer Nozzle?

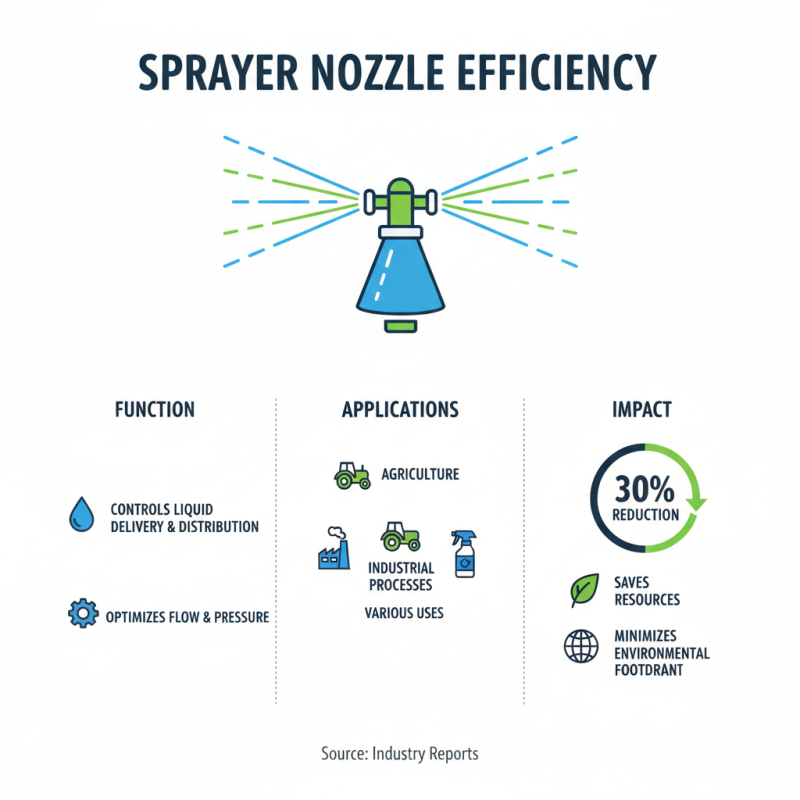

A sprayer nozzle is a crucial component in various applications, from agriculture to industrial processes. This device controls the delivery and distribution of liquids. By altering the flow and pressure of the spraying medium, it optimizes performance and efficiency. According to industry reports, efficient nozzles can reduce application rates by up to 30%, which saves resources and minimizes environmental impact.

Different types of sprayer nozzles exist. Fan nozzles create a wide spray pattern while cone nozzles produce a concentrated mist. Each type serves distinct purposes. Selecting the right nozzle can improve coverage and reduce waste. Research indicates that nozzle choice significantly affects outcomes, with incorrect options leading to lower efficiency.

Tips: Always consider the specific task at hand when selecting a nozzle. Regular maintenance can extend nozzle life. Inspect for wear or clogging, as these can affect performance. Even the best nozzles need adjustments. Ensuring proper alignment and pressure can yield better results.

Types of Sprayer Nozzles and Their Applications

Sprayer nozzles are essential tools for various applications. They come in different types, each designed for specific tasks.

One common type is the flat fan nozzle.

It creates a wide spray pattern, making it ideal for crops. It covers more area quickly, but it can lead to overspray if not calibrated correctly.

Another type is the hollow cone nozzle.

This creates a circular spray that is excellent for applying chemicals. It offers better coverage on the surfaces, but uneven pressure can cause inconsistent distribution. Users must be precise when using this type.

Then there are adjustable nozzles.

These allow users to change the spray pattern and flow rate on the go. This flexibility is useful, but it can be a bit overwhelming for new users. It takes practice to master the adjustments for optimal performance.

Each nozzle type highlights the balance between efficiency and control. Choosing the right one requires a good understanding of your specific needs.

How Sprayer Nozzles Function and Create Spray Patterns

Sprayer nozzles are vital components in various applications. They control the flow and distribution of liquids. Understanding how they function can improve efficiency. Nozzles create specific spray patterns to meet different needs.

When liquid passes through a nozzle, it accelerates due to the design. This speed changes as it exits. The shape of the nozzle determines the spray pattern, whether fine mist or wide coverage. Some nozzles produce droplets, while others generate a solid stream. Each pattern is suited for specific tasks.

However, achieving the perfect spray is not always easy. Environmental factors can affect the nozzle's performance. Wind, for instance, can disrupt coverage. Additionally, clogging is a real issue, often caused by debris. Regular maintenance is necessary but often overlooked. Streamlining these details can lead to better outcomes.

Sprayer Nozzles: Flow Rate Comparison

This chart displays the flow rates of different types of sprayer nozzles measured in gallons per hour (GPH). Understanding these flow rates is crucial for selecting the right nozzle for specific spraying tasks.

Factors Influencing Sprayer Nozzle Performance

Sprayer nozzles play a crucial role in agricultural applications. Their performance can greatly influence crop health and yield. Several factors affect how well a nozzle functions. For instance, the nozzle design impacts droplet size and distribution. A wider nozzle might create larger droplets, which can lead to uneven coverage.

Another important influence is the pressure at which the sprayer operates. Higher pressure generally produces finer droplets but can also increase drift. Depending on weather conditions, drift can reduce effectiveness and waste resources. The type of liquid being sprayed also matters. Some formulations may require specific nozzle types to ensure proper application.

Finally, maintenance is often overlooked but is key to performance. Clogged nozzles can lead to uneven spray patterns. Regular cleaning and inspection are essential for optimal performance. Without proper care, even the best nozzle designs can fall short of producing the desired results. The complexity of these factors reminds us that sprayer nozzles require thoughtful consideration for effective use.

What is a Sprayer Nozzle and How Does It Work? - Factors Influencing Sprayer Nozzle Performance

| Nozzle Type | Application | Flow Rate (GPH) | Pressure (PSI) | Spray Pattern | Coverage Area (sq ft) |

|---|---|---|---|---|---|

| Flat Fan Nozzle | Herbicide Application | 0.5 - 2.0 | 40 - 60 | Flat | 200 - 350 |

| Cone Nozzle | Insecticide Application | 0.3 - 1.5 | 30 - 50 | Cone | 150 - 300 |

| Hollow Cone Nozzle | Fungicide Application | 0.2 - 1.0 | 20 - 40 | Hollow Cone | 100 - 200 |

| Full Cone Nozzle | Cooling and Dust Control | 0.4 - 2.5 | 50 - 80 | Full Cone | 250 - 400 |

| Air Induction Nozzle | Low Drift Application | 0.5 - 3.0 | 40 - 70 | Air Induction | 300 - 500 |

Maintenance Tips for Sprayer Nozzles to Ensure Longevity

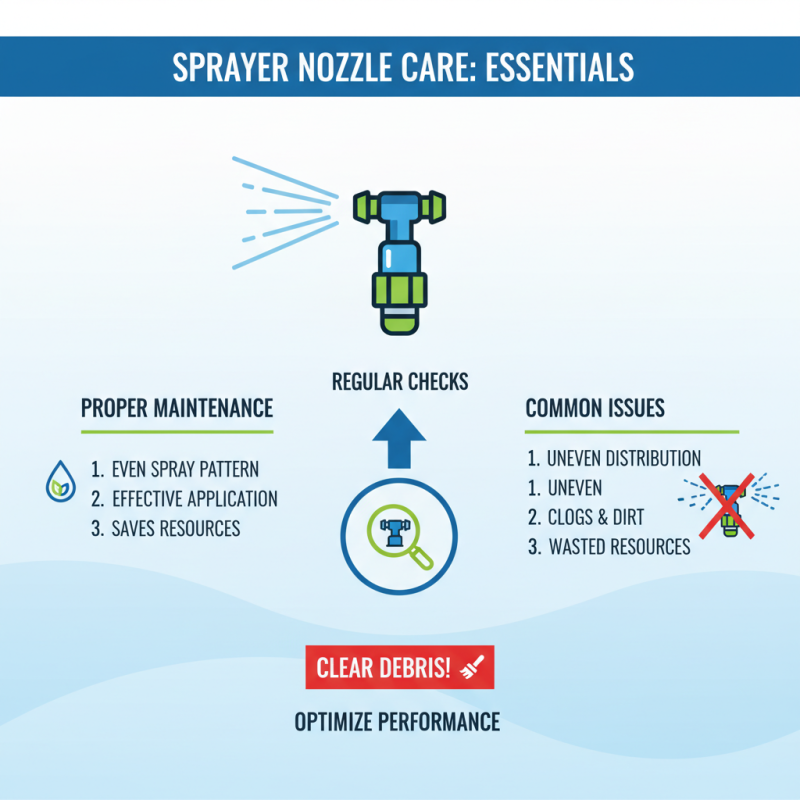

When it comes to sprayer nozzles, proper maintenance is crucial. A clean nozzle ensures an even spray pattern and effective application. Dirt and clogs can lead to uneven distribution, wasting your resources. Check nozzles regularly for blockages. Clearing debris is essential for maintaining performance.

One effective tip is to soak nozzles in warm, soapy water after use. This helps dissolve residue and prevent buildup. Rinse thoroughly to ensure no soap remains. Replace worn or damaged nozzles promptly. A small crack can cause leaks or inconsistent spraying.

Don't forget to store nozzles in a dry, cool place. Extreme temperatures can cause materials to degrade. Keeping everything organized can save time during your next project. Even small neglect can lead to costly mistakes. Pay attention to these details for lasting performance.

Related Posts

-

Understanding the Types of Sprayer Nozzles and Their Applications

-

Revolutionize Your Gardening with the Latest Sprayer Nozzles: Efficiency and Precision Unleashed!

-

Exploring the Benefits of ATV Boom Sprayers for Efficient Crop Management

-

Top 5 Essential Features to Look for in a 15 Gallon Sprayer for Your Garden

-

7 Best Boom Sprayers for Tractor that Enhance Crop Yields by 30 Percent

-

What is a Spot Sprayer and How Does It Work?