How to Choose the Right Boomless Spray Nozzle for Your Needs?

Choosing the right boomless spray nozzle can significantly impact your spraying efficiency. This nozzle type is designed to eliminate the need for traditional booms. It delivers precise application and minimizes overspray. However, selecting the correct model requires careful consideration of several factors.

Multiple options exist in the market, each with unique features. Some nozzles focus on wide coverage, while others target specific applications. A boomless spray nozzle offers versatility, but not every model will meet your needs. Assess your specific spraying tasks to align with the nozzle’s capabilities.

Remember, the wrong choice can lead to waste and inefficiency. Take time to reflect on your needs and the environment where you'll use the nozzle. This process can reveal crucial aspects you may initially overlook. A boomless spray nozzle can enhance your operation, but understanding your requirements and limitations is vital.

What are Boomless Spray Nozzles and Their Importance in Agriculture?

Boomless spray nozzles play a crucial role in modern agriculture. These nozzles provide effective applications without the need for large booms. Farmers can spray evenly across wide areas, ensuring better coverage and reduced drift. This efficiency is especially valuable when working in uneven terrains or dense crops.

These nozzles can help minimize waste. For instance, farmers can direct the spray exactly where needed. However, they may struggle to achieve the desired precision at times. Understanding the right settings is key. Adjusting the pressure can make a significant difference in application quality.

Tips:

- Consider using a pressure gauge to monitor output.

- Check the nozzle’s angle; it impacts coverage.

- Always test the nozzle in a small area before the full application to ensure effectiveness.

- Proper maintenance is essential for longevity.

- Clean nozzles regularly to avoid clogging or uneven spray patterns.

Key Factors to Consider When Selecting a Boomless Spray Nozzle

Choosing the right boomless spray nozzle requires careful consideration. Start by assessing the specific application. Different nozzles work better for various tasks, whether it’s for spraying pesticides, fertilizers, or herbicides. A common mistake is not matching the nozzle type to the job at hand. You might find yourself frustrated with uneven coverage or wasted materials.

Next, think about the spray pattern. Some nozzles create a wide pattern, while others focus the spray narrowly. Personal preference plays a role, but also consider the area size and shape. If you have uneven terrain or obstacles, a more adjustable nozzle might be necessary. It’s worth experimenting with a few types to see which feels right.

Don’t overlook the flow rate! This determines how quickly you can complete your task. A higher flow rate sounds appealing, yet it may not suit all situations. Slower application may improve effectiveness for some products. Keep in mind that not all nozzles are suitable for every liquid. This can lead to clogging or damage if you’re not careful. Reflecting on these factors will help you make a more informed choice.

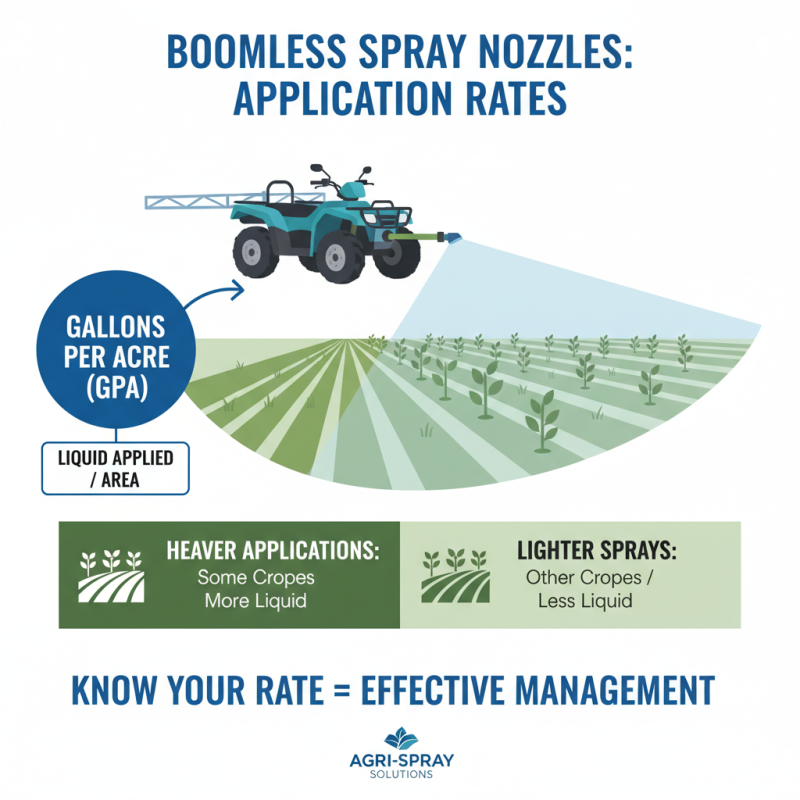

Understanding Application Rates: Gallons Per Acre and Nozzle Types

When selecting a boomless spray nozzle, understanding application rates is crucial. Gallons per acre indicates how much liquid is applied to your area. This measurement varies depending on your spray needs. Some crops require heavier applications, while others thrive with lighter sprays. Knowing the appropriate rate is key to effective management.

Different nozzle types influence the application process significantly. Air induction nozzles produce larger droplets, minimizing drift. These are ideal for windy conditions. Conversely, flat fan nozzles create finer droplets for more coverage. However, they are susceptible to drift. It's essential to weigh the pros and cons of each nozzle type based on your specific needs.

Assessing your requirements can be difficult. Choosing a nozzle without proper research can lead to wasted resources. Experimenting with various application rates may also yield unexpected results. You may find that your initial calculations were off. Take the time to test different setups before committing. Finding the right balance will enhance your spraying effectiveness while protecting your crops.

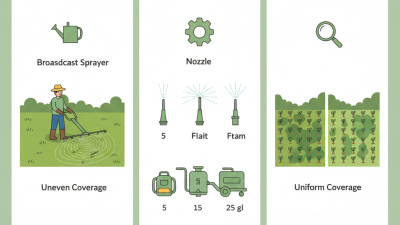

Comparative Analysis of Boomless Nozzle Patterns and Coverage Efficiency

Choosing the right boomless spray nozzle requires an understanding of nozzle patterns and coverage efficiency. Boomless nozzles offer distinct patterns like flat fan, cone, and air-induced. Each pattern serves different purposes. Flat fan nozzles provide even coverage, but they might struggle with wind drift.

When analyzing coverage efficiency, consider the area you will spray. Some nozzles cover a wide swath but may miss spots. Others are precise, but they require multiple passes. It's essential to evaluate your specific needs. In practice, tests with various nozzles can reveal inefficiencies. Some users find they still miss edges or overlap unnecessarily, leading to wasted materials.

Remember to factor in the terrain and wind conditions. Uneven ground can alter spray patterns significantly. Users may overlook this until they spot streaks in their work. This trial-and-error process is crucial. Not every nozzle will fit every situation, and adjustments might be necessary. Evaluate carefully, and reflect on what works best for you.

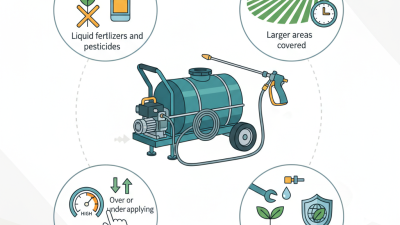

Maintenance Best Practices for Ensuring Optimal Nozzle Performance

Maintaining a boomless spray nozzle is crucial for achieving optimal performance. Regular inspection is key. Verify for clogs and wear. Clogs can disrupt the spray pattern. It’s easy to miss them, but it’s essential. A simple rinse can sometimes do the trick, yet thorough cleaning is better.

Check the nozzle tips regularly. They can become damaged over time. Wear and tear often go unnoticed until it’s too late. Replacing worn tips makes a significant impact. Make it a habit to compare spray patterns. Often, you might find uneven distribution, which indicates a problem.

Adjusting the pressure is another important aspect. Too high or too low can lead to inefficiencies. Identify what pressure works best for your tasks. Tracking usage and performance can help. Sometimes, I forget to note these details, which leads to issues later. Being mindful of these practices ensures your boomless spray nozzle performs at its best.

Related Posts

-

How to Optimize Your Use of a 3 Point Sprayer for Maximum Efficiency

-

How to Choose the Best Boomless Spray Nozzle for Your Spraying Needs

-

The Best 10 Master MFG Sprayer Features You Need to Know

-

2025 Top Sprayer Boom Kit Choices for Efficient Crop Spraying Techniques

-

Top 10 Best Broadcast Sprayers for Your Gardening Needs?

-

What is a 25 Gallon Sprayer and How Does It Work?