What is a Boom Sprayer Nozzle and How Does It Work?

Boom sprayer nozzles play a critical role in modern agriculture. They are essential for effective pesticide and herbicide application. According to a recent industry report, nearly 70% of agricultural professionals recognize the importance of nozzle technology for efficiency and accuracy in spraying.

The precision of boom sprayer nozzles directly impacts crop health and yield. These nozzles ensure even distribution of chemicals, reducing waste and ensuring coverage. However, many farmers still struggle with nozzle selection. A mismatch can lead to overspray or underspray, which can harm crops. In fact, studies show improper use of nozzles can decrease pesticide effectiveness by 30%.

This highlights a crucial learning opportunity. Many in the industry need better training on nozzle types and their specific applications. There’s a gap between technology and actual usage. While advancements exist, challenges remain in adopting these innovations effectively. Understanding boom sprayer nozzles is vital for optimizing agricultural practices. This topic warrants deeper exploration to improve both knowledge and outcomes in the field.

Definition and Purpose of Boom Sprayer Nozzles

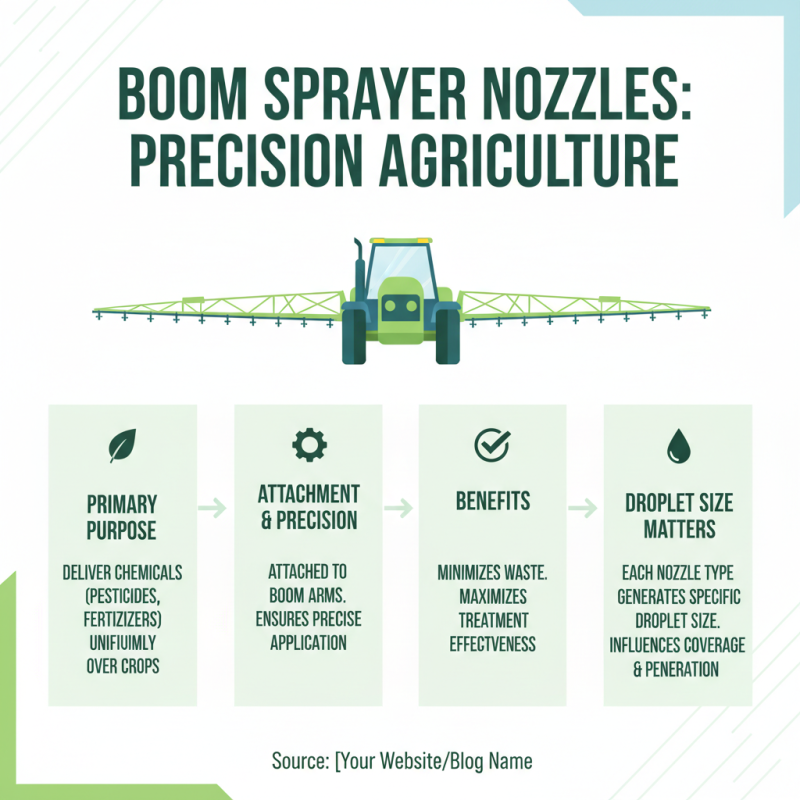

Boom sprayer nozzles are essential components in agricultural spraying systems. Their primary purpose is to deliver pesticides, fertilizers, and other chemicals uniformly over crops. They are attached to the boom arms of sprayers, allowing for precise application. This precision helps in minimizing waste and maximizing the effectiveness of treatments. Each nozzle type generates a specific droplet size, influencing coverage and penetration.

Understanding the various nozzle designs is crucial. Some nozzles create fine mist sprays, suitable for delicate crops, while others form larger droplets to prevent drift. The choice of nozzle impacts the efficiency of the spraying process. However, users often overlook these details. Incorrect nozzle selection can lead to uneven application. This can cause patchy crop growth or ineffective pest control.

Furthermore, maintaining boom sprayer nozzles is vital. Clogs can occur, affecting performance. Regular checks and cleaning can mitigate this issue. Skipping maintenance can lead to poor results and wasted resources. Experimenting with different nozzles may yield insights into which works best for specific situations, but it also requires careful monitoring. This process is not foolproof and may involve some trial and error.

Types of Boom Sprayer Nozzles and Their Applications

Boom sprayer nozzles play a crucial role in agricultural applications. They are essential for delivering pesticides, herbicides, and fertilizers. Different types of nozzles can affect the quality of coverage and the efficiency of the application. Understanding the types of nozzles is important for effective spraying.

Flat fan nozzles are popular for broad coverage. They create a fan-shaped spray pattern, ideal for large areas. This type works well for herbicides where even distribution is key. However, they can be prone to drift. Adjusting the pressure can help minimize this issue but may not eliminate it entirely.

Another type is the hollow cone nozzle. This nozzle produces a circular spray pattern with a fine droplet size. It’s particularly useful for targeting pests on dense crops. But users must be cautious. Excessive pressure can lead to breakage and uneven coverage. It’s essential to constantly monitor spray performance, adjusting as needed. Each nozzle type has its advantages and challenges that demand careful consideration.

The Mechanism of Action: How Boom Sprayer Nozzles Operate

Boom sprayer nozzles play a crucial role in agricultural spraying. They are designed to deliver liquid pesticides or fertilizers evenly across large areas. The functioning of these nozzles is influenced by several factors, leading to variations in coverage and efficiency.

When a boom sprayer operates, liquid passes through a series of nozzles attached to a horizontal bar. Each nozzle has a specific orifice size, which controls the flow rate. The liquid atomizes as it exits the nozzle, creating droplets that fall onto the crop. However, factors such as pressure and speed can affect droplet size. This can lead to uneven application, missing targets, or over-spraying.

The angle and distance of the nozzles also matter. Incorrect positioning can cause spray drift, reducing effectiveness. Regular maintenance is essential, yet overlooked. Clogged nozzles can disrupt flow and result in poor coverage. Sprayer operators must understand these variables to improve results. Regular calibration and testing will allow for better insights into performance and areas for improvement.

Factors Influencing Spray Patterns and Coverage

Boom sprayer nozzles play a crucial role in agricultural spraying processes. They directly influence spray patterns and coverage. Several factors can affect these aspects, including nozzle type, pressure, and droplet size. For example, according to a 2022 industry report, using the correct nozzle can reduce drift by over 30%, ensuring that pesticides land precisely where needed.

The angle of the nozzle also affects coverage. A flat angle can deliver a wide spray pattern, while a narrow angle may focus on targeted areas. Research indicates that a proper spray width can enhance coverage by up to 25%. Additionally, droplet size impacts the ability of the spray to penetrate foliage. Smaller droplets can reach the lower leaves but may drift away more easily. This delicate balance can make or break effective spraying.

Tips: Always choose the right nozzle for your application. Consider the winde conditions; a slight breeze can alter spray accuracy. Regular maintenance of your sprayer is crucial. Clogged nozzles can lead to uneven application. Review your results. If coverage is less than expected, adjust your spraying technique. Reflecting on these factors can greatly enhance efficiency in your spraying operations.

Maintenance Tips for Optimal Performance of Boom Sprayer Nozzles

Boom sprayer nozzles are essential for precision in agricultural spraying. Proper maintenance ensures these tools perform efficiently. Regular checks are vital. Look for clogs and wear. A tiny blockage can disrupt the entire spraying process. Clean nozzles often to prevent buildup.

Inspect nozzle tips for damage. Even minor cracks can affect spray patterns. Replace worn nozzles promptly; it could save time and resources. Adjusting the nozzle height can also improve performance. Ensure it matches the targeted application area. A small change can make a significant difference in the outcome.

Consider calibration as part of routine maintenance. Incorrect settings can lead to over- or under-application of chemicals. Collect data on spray coverage. If results are inconsistent, re-evaluate your approach. Sometimes, old habits hinder optimal performance. Stay curious and always look for ways to improve efficiency.

Related Posts

-

Top 5 ATV Weed Sprayers for Efficient Garden Care?

-

Top 10 Battery Garden Sprayers to Make Your Gardening Effortless

-

How to Choose the Best 25 Gallon Sprayer Tank for Your Needs

-

7 Essential Tips for Maximizing Efficiency with Your 40 Gallon Sprayer Tank

-

Top 5 Essential Features to Look for in a 15 Gallon Sprayer for Your Garden

-

Common Challenges Encountered with Battery Powered Sprayers in Commercial Use