The Best 10 Master MFG Sprayer Features You Need to Know

In the ever-evolving landscape of agricultural technology, the "master mfg sprayer" has emerged as an essential tool for maximizing efficiency and effectiveness in crop management. According to a recent report by AgEquipment Intelligence, the demand for advanced sprayers has surged by 25% over the last year, highlighting a critical need for features that enhance both functionality and user experience. As the industry becomes increasingly aware of the pivotal role that precision application plays in sustainable farming, evaluating the best features of master mfg sprayers has never been more essential.

Dr. Emily Hargrove, a leading expert in agricultural machinery and precision agriculture, emphasizes the importance of these advancements. She stated, "In today’s competitive agricultural environment, understanding the capabilities of master mfg sprayers can provide farmers with the strategic edge they need to optimize their operations and increase yield." With features ranging from advanced nozzle technology to integrated GPS systems, modern master mfg sprayers offer an array of options designed to meet the diverse needs of the agricultural community. As we delve into the ten must-know features of master mfg sprayers, it’s crucial for stakeholders to be informed about these innovations that are shaping the future of farming practices.

Top 10 Essential Features of Master MFG Sprayers You Must Understand

When choosing a sprayer for manufacturing applications, understanding the essential features can significantly impact efficiency and operational success. One of the top features to consider is the type of spray nozzle. According to industry studies, the correct nozzle can optimize application rates, improve coverage, and reduce overspray by up to 30%. This level of precision not only enhances product performance but also minimizes waste, ensuring that resources are used effectively.

Another critical feature is the tank capacity and material. Data from recent market analyses indicate that sprayers with larger, durable tanks made from corrosion-resistant materials can handle a wider range of chemicals and reduce maintenance costs by 25%. Additionally, ergonomic design plays an important role in operator comfort and productivity. A recent survey highlighted that sprayers designed for easy handling can reduce operator fatigue by 40%, thereby increasing the number of successful applications in a work shift. Understanding these features is vital for anyone considering a sprayer for their manufacturing operations, as they can lead to improved performance and cost savings.

Evaluating the Performance Aspects of Master MFG Sprayers

When evaluating the performance aspects of Master MFG sprayers, there are several key features that stand out. First and foremost, the efficiency of the spray pattern is critical. A well-designed sprayer should provide a uniform application that optimizes coverage while minimizing waste. An adjustable nozzle can significantly enhance this aspect, allowing users to switch between fine mists and heavier sprays depending on the task at hand. This versatility ensures that the sprayer can adapt to various project requirements, from delicate flowers to larger landscaping jobs.

Moreover, ease of use and maintenance cannot be overlooked. Sprayers with ergonomic designs reduce user fatigue, allowing for longer periods of operation. A lightweight construction combined with comfortable handles will make a noticeable difference during extensive use. Additionally, easy-to-clean components prevent clogging and extend the sprayer's lifespan, contributing to overall satisfaction and productivity.

Tips for maximizing sprayer performance include regularly checking and cleaning the nozzle to prevent blockages and ensuring that the equipment is properly calibrated for specific tasks. Always choose the appropriate sprayer setting based on the material being used; for example, dilute chemicals may require a different setup than pure solutions. Lastly, it’s beneficial to store the sprayer in a cool and dry environment to protect it from wear and tear, ensuring it remains in top condition for future projects.

The Best 10 Master MFG Sprayer Features You Need to Know - Evaluating the Performance Aspects of Master MFG Sprayers

| Feature | Description | Performance Rating | Durability |

|---|---|---|---|

| Adjustable Pressure | Allows users to customize the spray pressure according to different applications. | ★★★★☆ | High |

| Easy Cleanup | Designed for quick and efficient cleanup to save time. | ★★★★★ | Medium |

| Lightweight Design | Optimized for easy handling and portability. | ★★★★☆ | High |

| Wide Spray Pattern | Provides efficient coverage for larger areas. | ★★★★☆ | High |

| Durable Materials | Constructed from robust materials for longevity. | ★★★★★ | Very High |

| Compatible Nozzles | Supports a variety of nozzle types for different tasks. | ★★★★☆ | Medium |

| Ergonomic Grip | Designed to minimize strain during extended use. | ★★★★★ | High |

| Versatile Applications | Suitable for various spraying tasks from gardening to professional use. | ★★★★☆ | High |

| Adjustable Nozzle Settings | Allows change in spray pattern and flow for different materials. | ★★★★☆ | Medium |

| Integrated Safety Features | Includes features to promote user safety during operation. | ★★★★★ | High |

Understanding the Ergonomic Design Benefits of Master MFG Sprayers

When considering the features of high-quality sprayers, ergonomic design stands out as a critical factor that enhances user experience and efficiency. Master MFG sprayers, known for their thoughtful design, embody these principles by reducing strain during prolonged use. With handles that align with natural hand positions and lightweight materials, these sprayers allow operators to work for longer periods without discomfort. This is especially beneficial in demanding environments where precision and endurance are key.

Tips for optimizing your use of ergonomic sprayers include adjusting the handle height to match your stature, taking regular breaks to reduce fatigue, and practicing proper posture while spraying. Familiarizing yourself with the sprayer's balance and weight distribution can also lead to more controlled and effective application. Moreover, using padded grips can provide additional comfort, further alleviating pressure on the hands and wrists.

Innovative design features, such as trigger locks and easy-to-reach buttons, enhance usability while minimizing awkward movements. By integrating these ergonomic elements, sprayers not only enhance efficiency but also encourage a more sustainable working habit, leading to greater productivity in the long run. For anyone relying on manual spraying, investing in ergonomically designed equipment can make a significant difference in daily operations.

Comparing Technology Innovations in Master MFG Sprayers

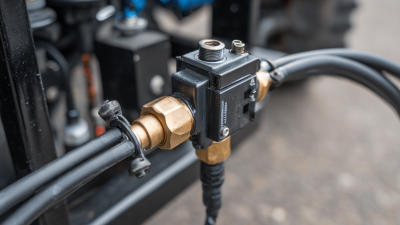

When discussing technology innovations in sprayer systems, the evolution of features in Master MFG sprayers stands out as a pivotal development in the industry. The incorporation of advanced nozzle technology significantly enhances the spray pattern and allows for better control over flow rates, which is essential for achieving uniform coverage while minimizing waste. Additionally, the integration of smart sensors improves operational efficiency by providing real-time data on application rates, pressure, and environmental conditions. This data allows users to make informed adjustments on-the-fly, optimizing performance and ensuring safety during usage.

Furthermore, the advent of automated systems marked a significant leap forward. Many modern sprayers now feature automated controls that can adjust the spray settings based on specific parameters such as terrain type and crop requirements. This automation not only reduces the labor intensity often associated with sprayer operation but also leads to more precise application. Technological advancements such as GPS integration and IoT connectivity have allowed operators to plan and execute spraying tasks with unparalleled accuracy, ensuring that resources are utilized effectively while minimizing the environmental footprint. As the field of agricultural sprayers continues to evolve, these technological features are setting new standards for performance and sustainability.

Maintenance Tips for Longevity of Master MFG Sprayers

To ensure the longevity of your sprayer, regular maintenance is paramount. First and foremost, always clean the equipment thoroughly after each use. Residual chemicals can corrode components over time, leading to malfunction. Utilize a suitable cleaning solution that dissolves the substances you’ve used, and rinse the sprayer parts with water. Pay special attention to filters, nozzles, and hoses, as clogs in these areas can drastically affect performance.

Furthermore, periodic inspections are crucial for identifying wear and tear before it becomes a serious issue. Examine the hoses and connections for any signs of leaks or cracks, and replace any worn components promptly. Lubricate moving parts according to manufacturer guidance to keep them operating smoothly, and store the sprayer in a dry, climate-controlled environment to prevent rust and degradation. By adhering to these maintenance tips, you can extend the life of your sprayer and ensure optimal performance throughout its use.

The Best 10 Master MFG Sprayer Features You Need to Know

This chart represents the key features of Master MFG Sprayers and their importance based on user feedback and maintenance considerations.

Related Posts

-

How to Optimize Your Use of a 3 Point Sprayer for Maximum Efficiency

-

Maximize Your Garden Efficiency with the Ultimate Guide to Spot Sprayers

-

Unlocking Precision: The Ultimate Guide to Boomless Sprayer Kits for Efficient Application

-

How to Choose the Right 3pt Sprayer for Your Farming Needs

-

5 Essential Tips for Maximizing Efficiency with Your 15 Gallon Sprayer

-

7 Essential Tips for Maximizing Efficiency with Your 40 Gallon Sprayer Tank